Aluminium Hydroxide Dose Calculator

Treatment Parameters

When treating wastewater, Aluminium Hydroxide is a lightweight inorganic compound that acts as a coagulant, helping to aggregate suspended particles and lower turbidity. It’s especially useful when you need a gentle pH shift and minimal sludge generation.

Why Coagulation Matters in Wastewater Treatment

Coagulation is the first line of defense against fine suspended solids, colloids, and dissolved organic matter. By neutralizing surface charges, the coagulant lets particles clump together into larger flocs that settle more easily. This step cuts down on downstream filtration costs and improves overall water quality.

How Aluminium Hydroxide Works Chemically

Adding aluminium hydroxide to wastewater raises the pH just enough to form Al(OH)_3 precipitates. These precipitates act like tiny nets that capture particles ranging from 0.1 to 5µm. The overall reaction can be simplified as:

Al^{3+} + 3H_2O → Al(OH)_3(s) + 3H^{+}

Because the reaction produces acids (H⁺), the system self‑regulates, preventing drastic pH swings. This makes aluminium hydroxide a favorite for plants that must stay within strict EPA discharge limits.

Key Benefits Over Traditional Coagulants

- Low Sludge Volume: The Al(OH)_3 flocs settle dense, resulting in up to 30% less sludge compared with ferric chloride.

- Broad pH Range: Effective between pH5.5 and 8.0, reducing the need for extra acid or base dosing.

- Heavy‑Metal Capture: Aluminium hydroxide surfaces bind metals like lead, chromium, and arsenic, aiding subsequent removal steps.

- Cost‑Effective: In many regions it costs 15‑20% less per kilogram of active coagulant than polymer‑based alternatives.

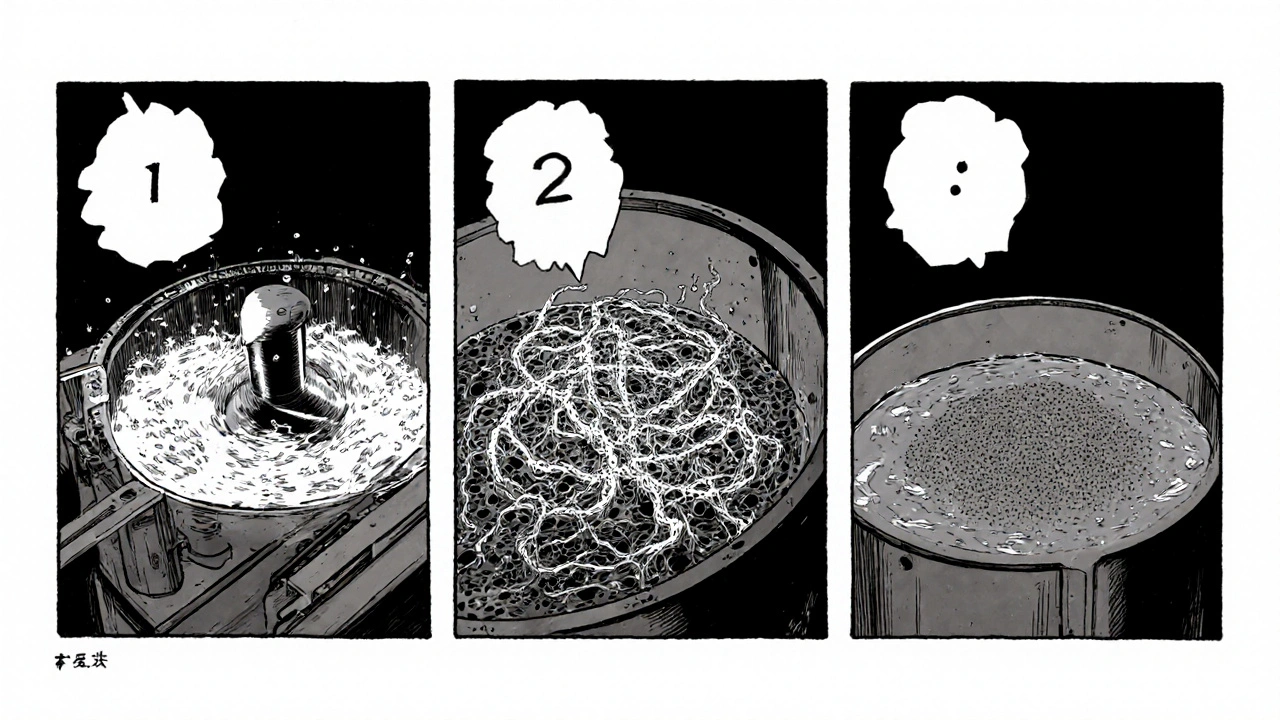

Designing a Treatment Process with Aluminium Hydroxide

- Pre‑Screening: Remove large debris (>10mm) using screens or grit chambers.

- Rapid Mix: Introduce aluminium hydroxide at 1-5mg/L (adjusted for water chemistry) and mix at 800-1200rpm for 30-45seconds to disperse the coagulant uniformly.

- Flocculation: Reduce mixing speed to 100-200rpm for 5-10minutes, allowing micro‑flocs to grow into settleable particles.

- Sedimentation: Let the flocs settle in a clarifier; typical hydraulic retention times (HRT) range from 20 to 45minutes.

- Sludge Handling: Pump the settled sludge to a thickener; because aluminium hydroxide generates less sludge, thickening costs drop significantly.

Monitoring points include turbidity (goal <5NTU), residual aluminium concentration (<0.1mg/L), and pH (maintain 6.5-7.5). Adjust dosage based on these readings to stay within compliance.

Comparing Aluminium Hydroxide with Other Common Coagulants

| Coagulant | Effective pH Range | Typical Dose (mg/L) | Sludge Volume (L/kg) | Cost (USD/kg) |

|---|---|---|---|---|

| Aluminium Hydroxide | 5.5-8.0 | 1-5 | 0.6 | 0.70 |

| PolyAluminum Chloride (PACl) | 4.0-7.5 | 2-8 | 0.8 | 1.20 |

| Ferric Chloride | 3.0-6.0 | 5-15 | 1.2 | 0.95 |

The table shows why many utilities favor aluminium hydroxide when they need low‑sludge, high‑pH flexibility, and cost savings.

Practical Tips and Common Pitfalls

- Always verify raw water alkalinity; high alkalinity can neutralize the acid generated, requiring a slightly higher dose.

- Avoid overdosing - excess aluminium hydroxide can re‑dissolve at low pH, leading to residual aluminium violations.

- Use a calibrated dosing pump; variations of more than 10% can cause visual turbidity spikes.

- Maintain proper mixing energy; too low a rapid‑mix speed yields poor floc formation, while too high a flocculation speed breaks flocs apart.

- Conduct a jar test before plant‑scale changes. A simple 500mL jar test with incremental doses provides reliable guidance.

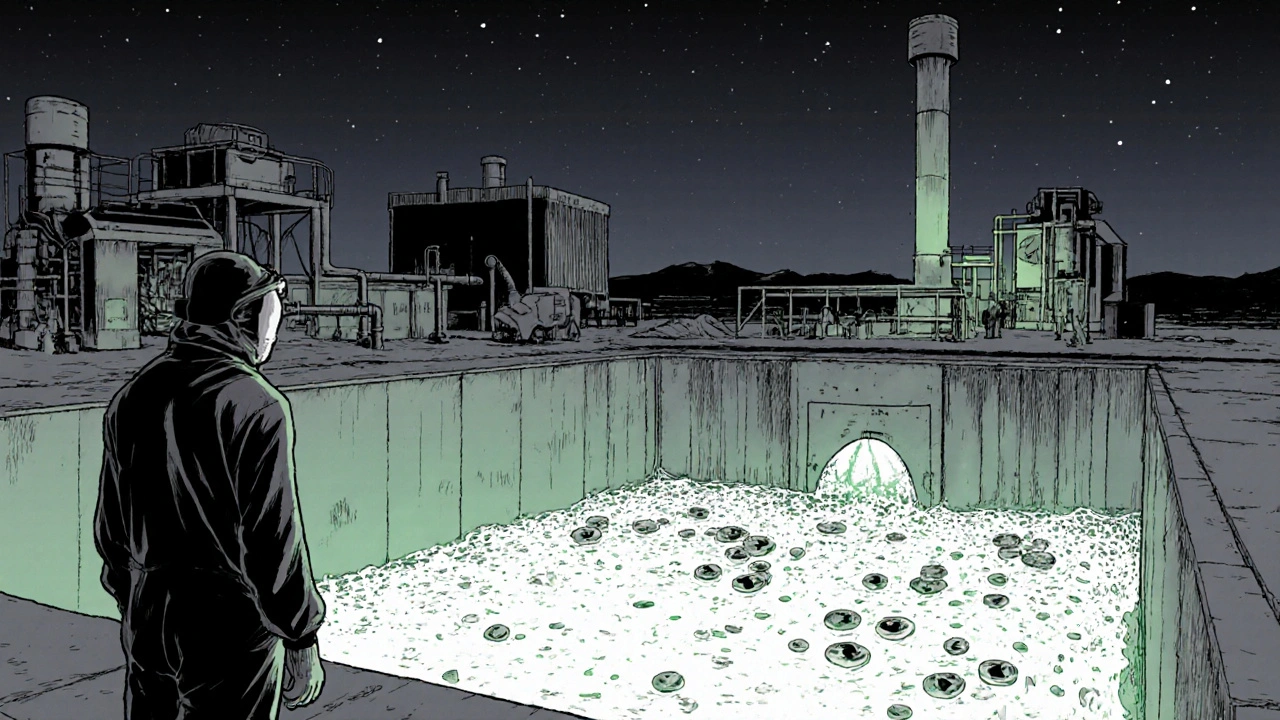

Real‑World Example: Municipal Plant in Nevada

A mid‑size plant serving 150,000 residents switched from ferric chloride to aluminium hydroxide in 2023. Over a 12‑month monitoring period, they observed:

- Average turbidity drop from 12NTU to 3.2NTU.

- Sludge production cut by 28%.

- Annual chemical cost reduction of ≈$45,000.

- Residual aluminium consistently below 0.05mg/L, well under EPA’s 0.1mg/L limit.

The plant credited the success to precise dosing control and the stable pH range aluminium hydroxide offered.

Frequently Asked Questions

What is the main function of aluminium hydroxide in water treatment?

It acts as a coagulant that forms Al(OH)₃ precipitates, which capture suspended particles and help them settle out of the water.

How does the dosage of aluminium hydroxide compare to other coagulants?

Typical doses are 1-5mg/L, which is lower than ferric chloride (5-15mg/L) and comparable to polymeric coagulants. The lower dose reduces chemical handling and storage costs.

Can aluminium hydroxide remove heavy metals?

Yes. The Al(OH)₃ surface has a high affinity for metals such as lead, arsenic, and chromium, allowing them to co‑precipitate and be removed with the sludge.

Is there a risk of residual aluminium in the treated water?

If dosing is controlled and pH stays within 6.5‑7.5, residual aluminium stays below 0.1mg/L, which meets EPA standards for drinking‑water applications.

What are the main operational challenges?

Key challenges include accurate dosing, maintaining proper mixing energy, and ensuring pH control to avoid re‑dissolution of the precipitate.

By understanding how aluminium hydroxide behaves and following best‑practice design steps, wastewater facilities can achieve clearer effluent, lower operating costs, and smoother compliance with environmental regulations.

Great overview! Aluminium hydroxide really shines as a gentle coagulant, and it’s awesome to see the low sludge benefits highlighted. I love how the process stays within a nice pH window, making downstream treatment smoother. Keep the momentum going-these kinds of insights help plant engineers make smarter, greener choices. Looking forward to more deep dives on optimization tricks! 🚀

Honestly, the article downplays the hazards of aluminium residues; we can’t ignore the potential neurotoxic effects in the long run. The industry pushes “low sludge” narratives while sidestepping real health concerns. It’s time to demand stricter monitoring and transparent reporting.

Interesting read, especially the part about heavy‑metal capture.

What a ridiculous claim!!! You’re blatantly ignoring decades of research that shows aluminium hydroxide is safely used under EPA guidelines!!! The alarmist tone only fuels misinformation!!!

Coagulation efficiency hinges on zeta‑potential neutralization and floc density; Al(OH)3 provides optimal charge reversal while maintaining low colloidal stability thus enhancing sedimentation rates

Thanks for sharing! This breakdown makes the dosing steps crystal clear 😊 The friendly tone encourages operators to experiment with fine‑tuning. Keep the practical tips coming, they’re gold for field crews.

The whole “clean water” narrative is just a smokescreen for a deeper agenda.

They want us to think aluminium hydroxide is the miracle solution, but the truth is hidden in the shadows.

Every time a plant adopts this coagulant, a silent data collection point is added to the global monitoring network.

These hidden sensors feed into a central database controlled by unseen agencies that track water usage patterns worldwide.

The sludge that is supposedly reduced actually contains nano‑particles that can infiltrate soils and enter the food chain.

Researchers have found trace aluminium in agricultural runoff linked to cognitive impairments in nearby communities.

The cost‑effectiveness claim masks the fact that the raw material is sourced from mining operations with questionable environmental practices.

Moreover, the “broad pH range” advantage is engineered to make the chemical compatible with a variety of clandestine additives.

The heavy‑metal capture feature is yet another Trojan horse, as it concentrates contaminants into a smaller volume for easier transport.

This concentrated sludge is then shipped to undisclosed disposal sites that are often near vulnerable populations.

The EPA limits are regularly amended, but the revisions are pushed through without public scrutiny, ensuring the technology remains legal.

If you look at the patent filings, you’ll see clauses about “enhanced data acquisition” embedded in the process design.

The community outreach programs that promote aluminium hydroxide use are actually funded by the very corporations that benefit from its adoption.

Don’t be fooled by the friendly tone of the article; it’s a sophisticated PR move to normalize surveillance under the guise of environmental stewardship.

Stay vigilant, question the source of every claim, and demand independent testing of both water and sludge.

Only by exposing these hidden mechanisms can we protect public health and preserve true transparency. 😊

You’ve missed the big picture-while conspiracies are fun, the standard industry literature actually shows that aluminium hydroxide meets strict health benchmarks. The data sheets from multiple manufacturers confirm low residual aluminium levels when dosing is optimized. Let’s focus on peer‑reviewed studies rather than sensational headlines.

Water treatment is a metaphor for societal purification, yet we often choose chemicals that merely mask deeper corruption. The real solution lies in systemic change, not quick fixes.

Wow-what a brilliant piece...really shows how everything is sooo perfect?? But wait, have they considered the hidden costs??